Handmade in Europe. Made according to the highest standards of glassmaking: The Josephine unites the finest craftsmanship and visionary design.

Each glass is a unique piece, mouth-blown and hand-shaped. The process begins with a special mixture of raw glass and requires a distinct choreography from melting to polishing.

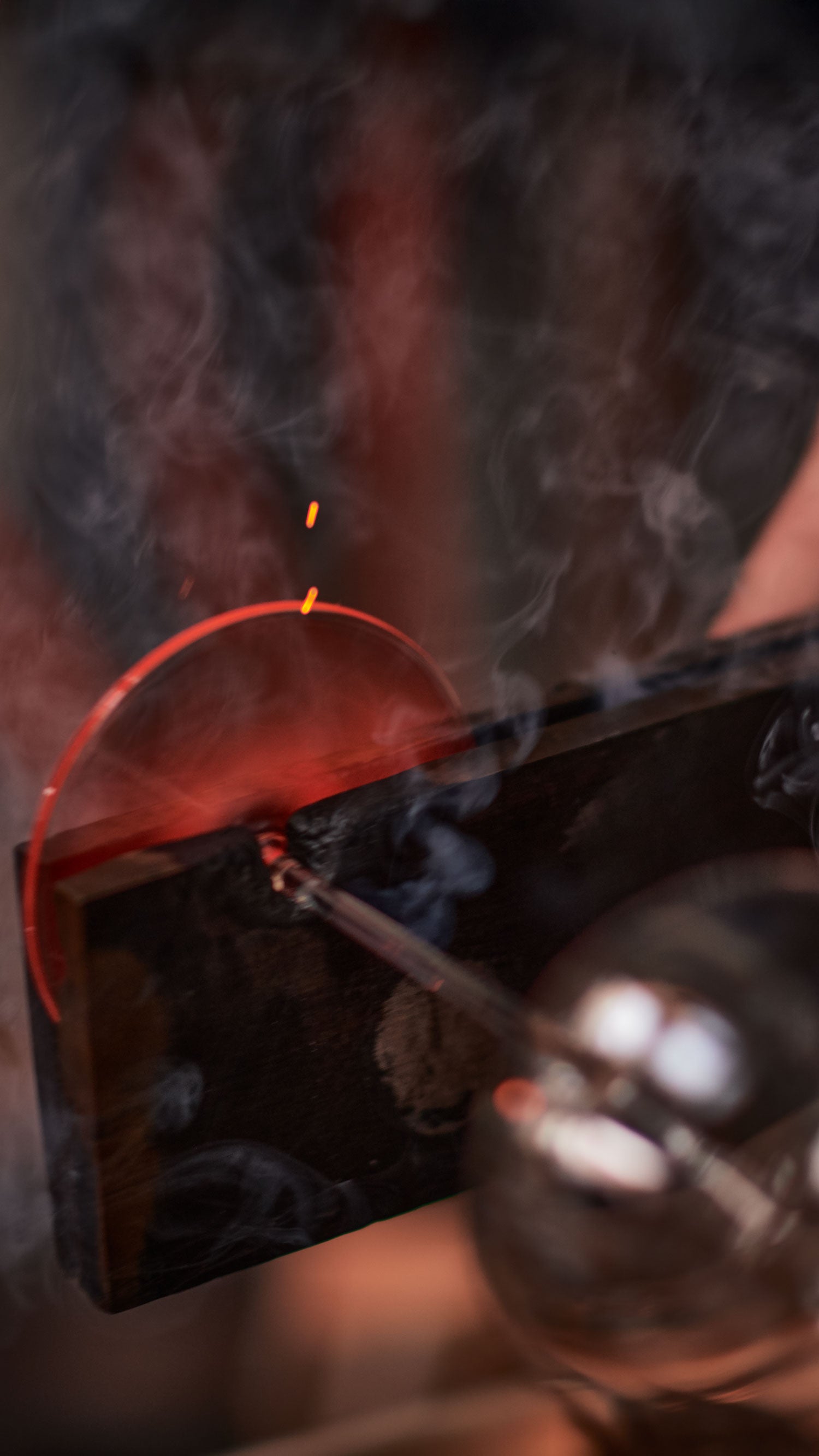

The process of making a wine glass by hand involves the power of fire and the critical moment when molten glass meets the mold. Precise hand movements then provide the final touch, with four to six skilled glassmakers collaborating on each individual glass. This dedication to the material and its shape results in wine glasses that are unparalleled in clarity and brilliance.

Mouth-blown glasses are a manifestation of history, tradition, and craftsmanship.

Craftsmanship

Traditional glassmaking is a millennia-old and precious craft to which we are deeply committed. The creation of a single glass takes several days and requires years of experience, exceptional skill, and delicate artistry from our glassmakers. Using simple, almost archaic tools, they produce glasses of the highest delicacy and precision. We choose only the finest artisans from their trade for this intricate work.

Glasses with soul

Regardless of how good a machine-made glass can be today, it cannot compare to a meticulously handcrafted Josephine glass. Mouth-blown wine glasses are remarkably thin-walled, flexible, and lightweight, which enhances the enjoyment of wine. Furthermore, it is the philosophy of craftsmanship and the humility associated with centuries-old traditions that resonate with every sip from a Josephine glass.

Handcrafted originals

Since each of our glass products is handcrafted, form and size may vary slightly, and occasional small bubbles may appear in the glass. This does not affect its functionality in any way; rather, it is a testament to the genuine craftsmanship that makes each glass a unique original.

The artistry behind each Josephine

Careful quality inspection and eco-friendly, safe packaging.

Only the glasses that meet our high quality standards and are characterized by functionality and lightweight design leave the workshop. Glasses that do not pass the test are melted down and recycled.

To protect the products during transport, all items are sustainably packaged in multiple layers of tissue paper and protective paper to ensure a safe journey to wine lovers around the world.